The process of risk management is so fundamental to safety in the electrical industry that it is important that every worker use a risk management approach to address workplace health and safety. The risk management process is an ongoing process and all workers should have a strong understanding of the purpose and steps of risk management.

A risk management approach should be applied long before any workers arrive at site. A safe and healthy workplace does not happen by chance or guesswork. You have to think about what could go wrong at your workplace and what the consequences could be. Then you must do whatever you can (in other words, whatever is ‘reasonably practicable’) to eliminate or minimise health and safety risks arising from your business or undertaking.

- identify hazards – find out what could cause harm

- assess risks if necessary – understand the nature of the harm that could be caused by the hazard, how serious the harm could be and the likelihood of it happening

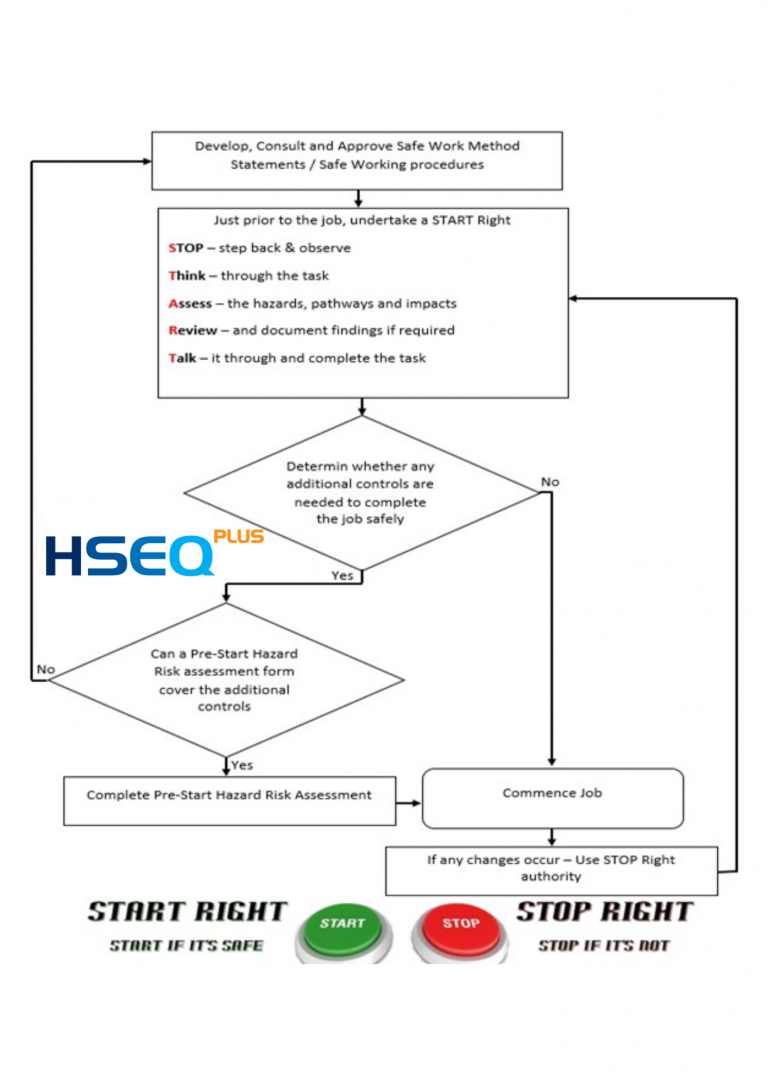

- control risks – implement the most effective control measure that is reasonably practicable in the circumstances by developing, consulting and implementing either Safe Work Method Statements (SWMS) or Safe Working Procedures SWPs as appropriate.

- review the control measures to ensure they are working as planned in an ongoing manner.

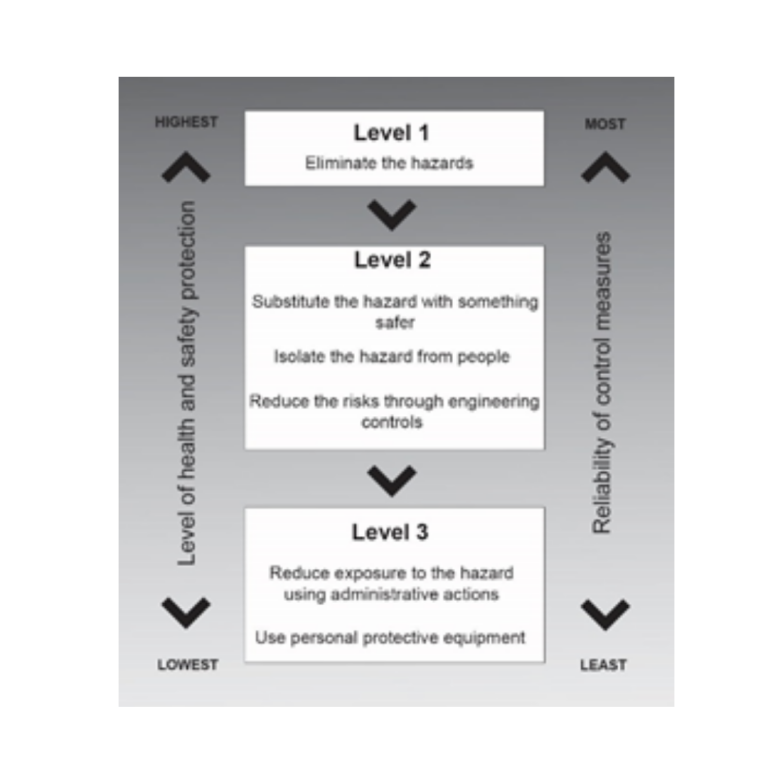

Eliminate the hazard wherever practicable and if not possible, specify risk control measure/s to minimise the risk of harm to the lowest possible or tolerable level using the following hierarchy (listed from Strong to Weak):

The outcome of this risk management approach should result in the development of a safety management system with policies, safe working procedures, safe work method statements, training and equipment provided to the workers.

Pre-written templates are available in NECA’s HSEQ plus Safety Management System.